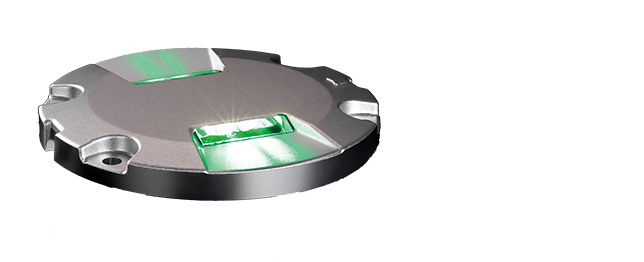

The fixture is 4.0mm above grade, meeting the FAA style 3 and ICAO style 4 protrusion requirements which categorises fixtures to be ≤6.3 mm. The low protrusion of the fixture helps prevent damage to the light during runway cleaning operations, especially in winter conditions. It also helps provide a better ride to the aircraft, by helping to reduce vibrations to the landing gear.

There is no negative slope on the fixture which assists in the prevention of silt, dust and water accumulating in front of the lens, ensuring minimum loss to the photometric performance.

Designed to meet the harsh environment the fixtures will operate in a temperature range of -55 °C to +55°C (-67 °F to +131°F) and has an ingress protection of IP67 (IEC 69598-1)

A standard FAA L823 style 1 connector is used to connect the fixture to the isolating transformer ensuring a water tight connection is made. On certain applications an option for an additional power lead can be requested.

The fixture operates between 2.8 – 6.6 amps which can be powered by either an IGBT type CCR, Ferroresonant or thyristor unit powering the airfield ground lighting (AGL) series circuit. The fixture is fully dimmable and follows the response curve of tungsten halogen lights as detailed in engineering brief 67 outlined in the Advisory Circular (AC) FAA 150/5345-53.